Aiming at the heavy - load scenarios in small and medium - sized warehousing and manufacturing industries, the Lead 2.5 - ton electric forklift, with the national - standard steel structure + dual - motor coordination system as the core, realizes two operation modes of 3m full - load / 6m load - limitation, overcoming the industry problem of heavy - object high - position stacking in narrow spaces.

Three Core Competitiveness

Ultra - long Endurance, Electric Revolution

60V high - voltage system + 10 sets of Chaowei 70A maintenance - free batteries, no pressure for 8 hours of continuous operati

Dual - motor independent control (Kecheng 5000W drive + 4000W lifting motor), energy consumption reduced by 22% compared with the same type

Heavy - load Design, Military - grade Reliability

12# national - standard steel gantry (tilt angle 6° - 12°), 2.5 - ton full - load anti - deformation capability

Cast - steel integrated square - plate front axle + steel - plate rear axle, 15° no - load / 13° full - load climbing performance

Extreme Dexterity, All - scenario Adaptability

Compact size (2.43×1.2m) matched with 1.65m wheelbase, 2m narrow - aisle right - angle stacking

650 - 10 front wheel + 500 - 8 rear wheel combination, 9.5cm ground clearance, passability increased by 40%

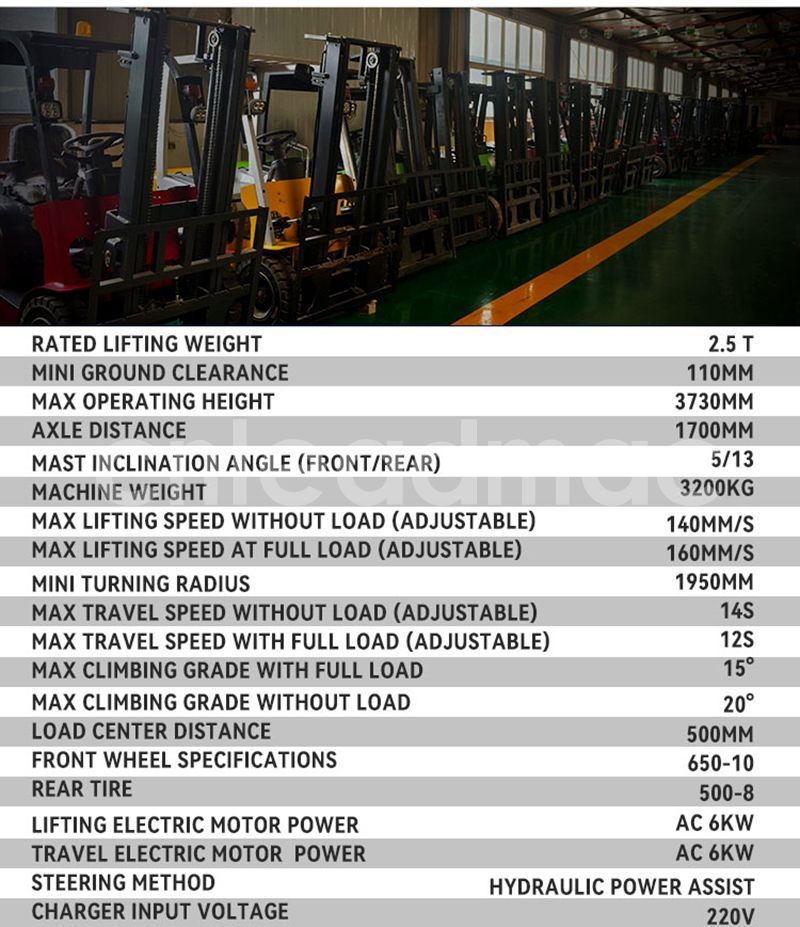

Technical Parameter

Core load - bearing: 2.5T@3m / 200kg@6m

Maneuverability: Turning radius ≤1.8m / Minimum passage 2m

Safety design: Gantry fracture load ≥8T / Oil brake response <0.3s

Maintenance cost: Maintenance - free battery design, saving maintenance costs

Recommended Industry Solutions

E - commerce transfer warehouse: 3m standard lift height + fast - charging mode, meeting the needs of high - frequency loading and unloading for 18 hours a day

Automotive parts factory: 6m load - limitation mode solves the pain point of top - layer access in the mold rackCold - chain logistics center: 9.5cm ground clearance to deal with slipping on condensate water ground

LD Lawn Mower: Robust Power Se

LD Lawn Mower: Robust Power Se

1 T Twin Cylinder Electric For

1 T Twin Cylinder Electric For