LD - S25 Skid Steer loader Upholding the design concept of "small size, great power", this equipment precisely focuses on the needs of small and medium - sized engineering operations. With its excellent power performance, compact and flexible body design, and reliable hydraulic system, it provides efficient solutions for various fields such as construction, agriculture, and municipal maintenance.

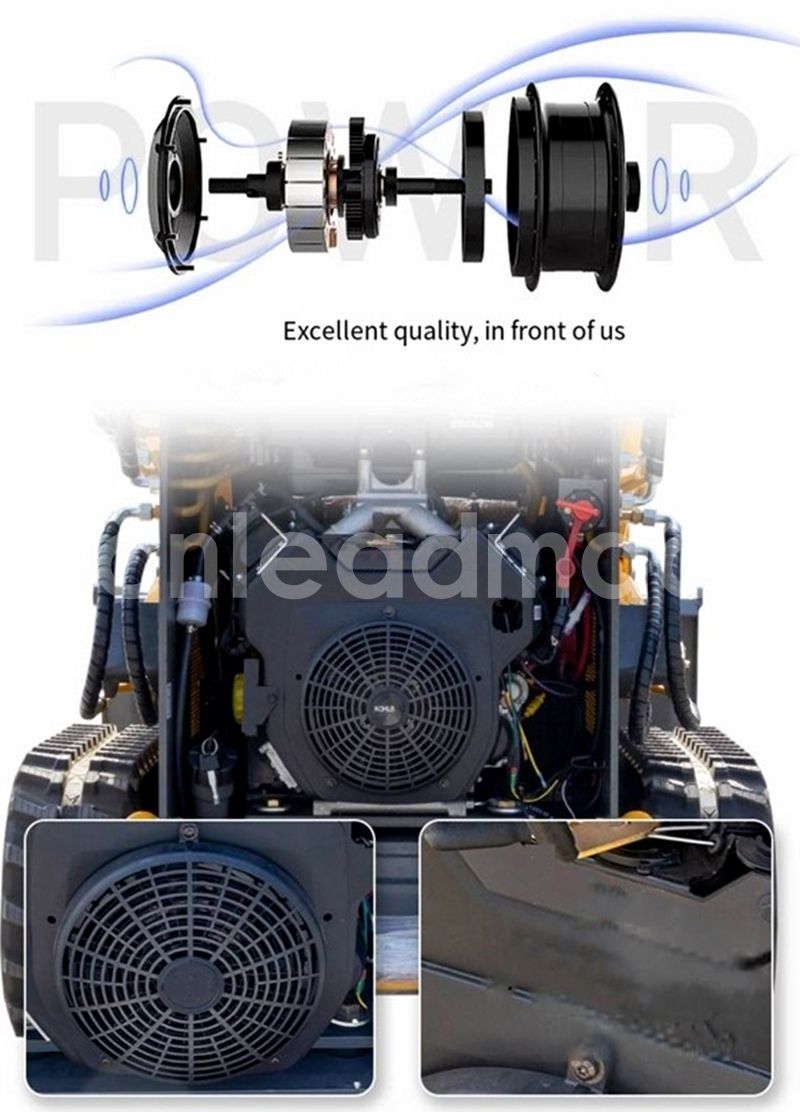

I. Diverse Engine Options to Suit Complex Working Conditions

In terms of engine selection, the LD - S25 offers users two high - performance engine options: the Laidong 385 (18.8kW) and the Yanmar 380 (17.8kW). The Laidong 385 engine is powerful and is especially suitable for high - intensity and high - load working scenarios. It can provide continuous and stable power output for the equipment, ensuring that the equipment runs smoothly and efficiently in heavy - duty operations such as earthwork handling in large - scale construction sites and material handling in mines. The Yanmar 380 engine, with its significant advantages of low vibration and low noise, becomes the ideal choice for urban environment operations and areas with strict noise control requirements, such as urban municipal engineering maintenance, construction operations around campuses and hospitals, etc. While ensuring the progress of operations, it minimizes interference with the surrounding environment to the greatest extent. This diversified engine selection model allows users to flexibly balance power and cost according to actual working conditions, achieving a win - win situation of efficiency and benefit.

II. Compact Body Design Unlocks the Potential of Narrow - Space Operations

The overall dimensions of the machine are only 2730mm (total length) × 950mm (total width) × 1865mm (total height), with a wheelbase of 730mm and a turning radius as low as 2000mm. It can easily shuttle through narrow spaces such as construction pits, greenhouse sheds, and urban alleys. The solid - tire configuration (570×155) has both wear - resistance and anti - slip characteristics. Combined with a ground clearance of 130mm, it can maintain stable driving even on complex terrains such as muddy and gravel - filled areas, solving the pain points of traditional equipment such as "inability to enter, turn, or drive stably".

III. Professional Hydraulic System for Precise Control and Efficient Operations

The hydraulic system adopts a working pressure of 18MPa and is equipped with a Pai - 630 travel motor to provide strong driving force. The machine features a simple, reliable and highly responsive central control design. This design enables operators to precisely control the bucket swing (130°) and discharge angle (30°), efficiently completing operations such as material loading and unloading and site leveling. The 0.22m³ bucket volume is matched with a rated load of 390kg (maximum load 490kg), taking into account the operation efficiency and safety of small and medium - sized projects. It is especially suitable for high - frequency light - load operations such as municipal greening transplantation, agricultural feed handling, and construction site muck cleaning.

IV. Optimized Detail Design for Dual Improvement of Durability and Comfort

The maximum discharge height of 2000mm and discharge distance of 2400mm meet the requirements of conventional operations like truck loading. The 20° departure angle design minimizes the risk of the fuselage getting scratched, thus extending the equipment's service life. The cab, features an enclosed structure with a canopy. This enclosed design not only provides protection against dust, sunlight and wind but also significantly improves the driver's field of vision and operating comfort. The packaging size (2880×1100×2015mm) is designed for transportation convenience, and the machine's overall weight of about 1.2 tons helps reduce logistics costs while ensuring stability during transportation.

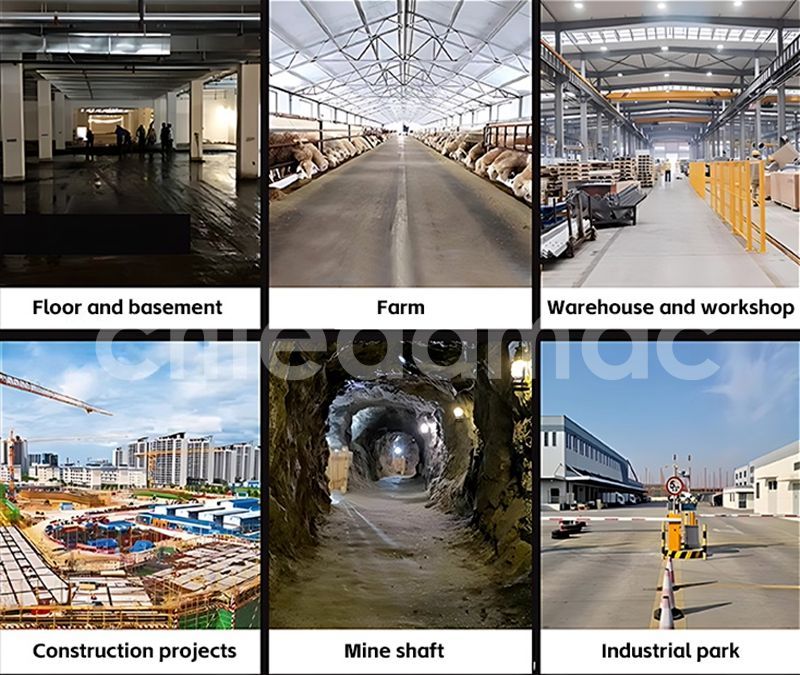

Diversified Application Scenarios

Construction Engineering: Material loading and unloading for foundation pit backfilling, construction waste cleaning between floors, and material transfer in small concrete mixing stations.

Agricultural Field: Manure treatment in livestock farms, fertilizer handling in fruit and vegetable greenhouses, and stacking and transportation after forage harvesting.

Municipal Maintenance: Removal of broken materials during sidewalk tile replacement, earthwork operations for green belt seedling transplantation, and rapid switching of snow - removal accessories for winter road maintenance.

Whether it is refined operation requirements or complex working condition challenges, the LD - S25 will be a reliable partner to help you improve efficiency. Contact us now to obtain detailed technical information and quotation plans!

LD Lawn Mower: Robust Power Se

LD Lawn Mower: Robust Power Se

1 T Twin Cylinder Electric For

1 T Twin Cylinder Electric For