In small and medium-sized warehousing, manufacturing, and logistics scenarios, an electric forklift that "handles heavy loads, navigates narrow spaces, and offers durability with easy maintenance" is key to boosting operational efficiency. Today, we take you inside Lead Factory to showcase 8 core components in real photos, revealing how we craft "all-weather reliable" forklifts with millimeter-level precision to help global customers achieve cost reduction and efficiency gains.

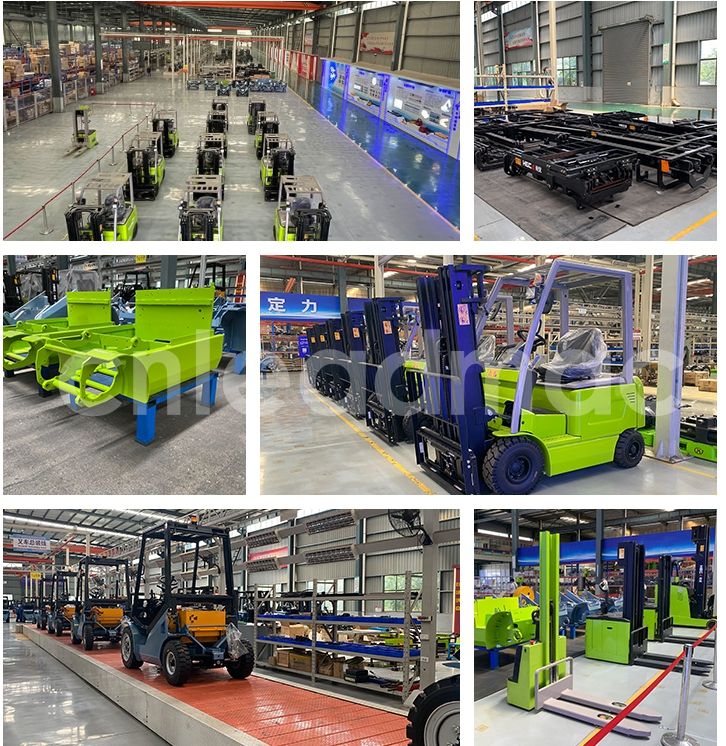

Precision Manufacturing: Quality You Can See

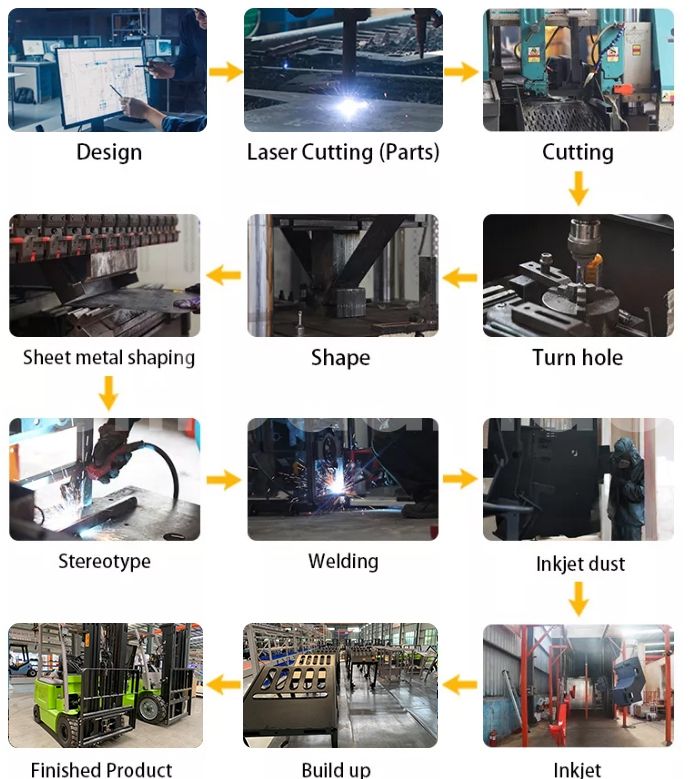

Cutting Process: Advanced CNC Technology in Full Swing

Equipped with imported CNC laser cutting machinery, we process metal sheets by focusing high-energy laser beams to melt or vaporize materials with millimeter-level precision. Critical cutting surfaces undergo multiple inspections via professional equipment, ensuring flawless dimensions for downstream processes—delivering the efficiency and accuracy demanded by industrial metal processing.

Assembly Workshop: 0.01mm-Level Precision Control

Each forklift undergoes 72 hours of assembly and debugging. We use laser alignment to calibrate gantry verticality (error ≤0.05mm) and torque wrenches for bolt tension control. Before leave the factory,every unit passes 1,000-cycle full-load lifting fatigue tests, achieving a failure rate below 0.1%.

Core Component Breakdown: Design Solving Real-World Pain Points

1. Gantry System: The Stable Heart of Heavy-Duty Operations

6°–12° adjustable tilt design allows quick pallet picking when tilted forward and secure load locking when tilted back, ideal for high-position storage in racking systems.

Constructed from high-strength steel, the gantry resists fractures exceeding 8 tons—3x the rated load—extending service life by 2 years in harsh conditions.

2. Transmission Chain: Millimeter-Level Wear Resistance

Features premium imported chains treated with carburizing quenching, enhancing wear resistance by 40%. An automatic tensioning system minimizes maintenance needs.

Dual-chain synchronous drive ensures smooth fork lifting, with a tilt angle <1.5° under full load to protect delicate cargo.

3. Ergonomic Steering Wheel: 8 Hours of Fatigue-Free Operation

360° adjustable hydraulic steering reduces rotation resistance by 25%, enabling one-handed control, the interface meets ISO 2867 ergonomic standards for effortless long-hour operation.

4. All-Terrain Tires: Unmatched Traction Across Surfaces

Front high-elastic solid tires (20% thicker in load-bearing areas) and rear non-slip tires, combined with 9.5cm ground clearance, adapt to warehouse epoxy floors, outdoor concrete, and light mud—boosting grip by 30% on wet surfaces.

Optional explosion-proof or silent tires cater to special environments like cold storage and electronics factories.

5. Counterweight Cast Iron: The Invisible Safety Guardian

Crafted from high-quality ductile iron through 1,300℃ high-temperature casting, with density uniformity error <0.5% to stabilize the center of gravity and prevent tipping.

Counterweight ratio adheres to international safety standards, with a tip-over resistance coefficient ≥1.4 at 3m lift height (industry standard: 1.2), ensuring safety margins in extreme conditions.

6. Shell Design: Durability Meets Aesthetics

Built with 0.8mm galvanized steel and triple-layer eco-friendly paint, passing 1,000+ hours of salt spray testing for 3+ years of rust-free outdoor use.

Quick-release engine cover enables 3-minute access to batteries/motors, improving maintenance efficiency by 50%.

Scenario-Based Solutions: Redefining "Small Footprint, Big Performance

E-commerce Warehouses: Compact body design enables right-angle stacking in 2m narrow aisles, maximizing Stereoscopic Warehouse space utilization.

Automotive Parts Factories: Efficient load-limiting mode and precise control ensure safe top-layer access in mold racks, reducing reliance on overhead cranes.

Cold Chain Logistics: Moisture-resistant shells and non-slip solid tires guarantee stable operation on condensation-prone floors and in -20℃ low-temperature environments.

Manufacturing Workshops: Energy-efficient dual-motor systems significantly cut power consumption, meeting high-frequency operation demands while lowering operational costs.

Why Choose Us? Three Promises for Peace of Mind

1:Transparent Craftsmanship: Full-process video tracing from steel to finished product, with a unique quality report for every forklift.

2: Flexible Customization: 12+ customizable parameters (fork length, battery capacity, seating, etc.) with 72-hour rapid prototyping.

3: Global After-Sales Support: Localized service networks in 50+ countries, 24/7 fault response, and 5-year warranties for core components.

The All-New Ld-D30 Diesel Fork

The All-New Ld-D30 Diesel Fork

Snow Removal Without Worry – T

Snow Removal Without Worry – T

Say Goodbye To Range Anxiety!

Say Goodbye To Range Anxiety!